- 首頁

- 產品櫥窗

- Multi-Slide CNC

- CNC Multi-Slide Automatic Lathe

CNC Multi-Slide Automatics

The LICO LNT Series Automatics are specially designed for metalworking industries such as for aviation, vehices, computers, plumbing fittings, optical instruments and many others.

It is ideal for machining all kinds of materials, ranging from aluminum, brass, steels, high alloy steels to stainless steels.

Rigidity , Stability, and Lifetime Deformation-free

All this Can Be Found On LICO CNC LNT-S series.

Lico engineers have combined years of practical automatic lathe design experience with latest structural design concepts to ensure that Lico automatic lathes provide optimum structural and machining accuracy.

Ruggedly constructed machine bed with scientifically rib reinforcement achieves the best possible stability.

Z-axis slide base and bed are one-piece constructed for added rigidity.

- Extra wide span between Z-axis linear ways with full travel support largely increases machining stability and accuracy.

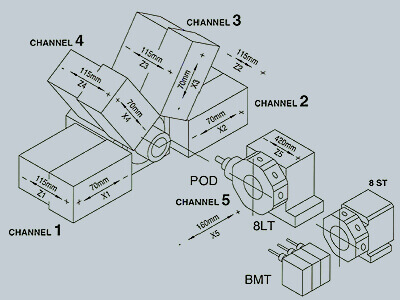

- X2 Z2, X3 Z3, X4 Z4 ball screws are directly driven by Siemens servomotors.

- Precision linear guideways on Z1axis.

- Automatic lubrication to all slideways.

The Pick Off Device with collet mounted on the turret, actuated by a hydraulic system, is servo driven synchronously with the main spindle while catching the work piece and performing the cut off operations.

After indexing to the opposite direction, the work piece is ready for back machining.

The back machining tool platform allows for mounting up to 4 gang tool holders or up to 3 live tool units.

Back Machining

The pick-off device catches the workpieces before cutting off.

After indexing to the opposite direction, the workpiece is ready for back machining.

The back machining tool platform allows for mounting up to 4 gang tool holders or up to 3 live tool holders.

| 功 能 | 單 位 | 型 號 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| LNT36S | LNT42S | LNT51S | LNT65S | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 加工範圍 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 筒夾通孔夾持最大外徑 | mm | Ø36 | Ø42 | Ø50.8 | Ø65 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 主軸 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 主軸中心高(約) | mm | 1000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 主軸塔配筒夾型式 | _ | F42 | F48 | F58 | F72 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 主軸鼻端規格 | - | _ | ISO A2-5 | ISO A2-6 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 主軸通孔 / 拉管通孔 | mm | Ø44/Ø37 | Ø53/43 | Ø60/Ø52 | Ø78/Ø66 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 主軸連續輸出功率 | S840Dsl | 15 kW (20 HP) | 20 KW (27 HP) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M730 | 11 KW (15 HP) | 15 KW (20 HP) | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 主軸最高轉速 | rpm | 6000 | 5000 | 4500 | 4000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 複合滑座 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 滑座行程,Z軸 / X軸 | mm | 115 (4.52”) / 70 (2.75”) | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 快速移動速度,Z軸 / X軸 | M/min | Z:25 / X:15 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 車削進給速度,Z軸 / X軸 | _ | 5 M / Min | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 程式移動最小增量值 | mm | 0.001 (0.0001”) | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 主刀塔 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 刀具位置數 | - | 8 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 刀柄型式 | mm | VDI-30 x 55 / □20 / Ø25 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 主刀塔行程,Z軸 / X軸 | mm | LNTS | 500 / 160 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| LNTS-T3 | 750 / 160 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 外徑刀桿橫切面尺寸 | mm | □ 20 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 主刀塔換刀時間 | _ | 0.28 sec / 180° - 0.6 sec | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 第二刀塔 / T2E刀塔 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 刀具位置數 | - | 8 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 刀柄型式 | mm | VDI-30 x 55 / □20mm / Ø25mm | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 第三刀塔 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 第三刀塔行程,Z軸 / X軸 | mm | 200 / 150 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 外徑刀桿橫切面尺寸 | mm | □ 20 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 第三主刀塔換刀時間 | _ | 0.28 sec / 180° -0.6 sec | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 副主軸 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 筒夾型式 | _ | TNS42 / TNS42E65 / HAINBUCH32 / TF3B-4 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 副主軸最大夾持 | mm | Ø42 / Ø65 / Ø32 / Ø65 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 副主軸馬達(刀具驅動) | kW | S840Dsl | 3.3 Kw (4.4HP) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M730 | 3.7 Kw (5HP) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 副主軸最高轉速 | rpm | 3000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 背後加工刀具 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 外徑刀桿橫切面尺寸 | mm | □ 20 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 最大搪孔刀桿徑 | mm | Ø 25 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 佔地面積及機械重量 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 體積(長×寬×高) | mm | 2804x1848x1935 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 機械淨重 / 包裝毛重 | Kg | 淨重:3200 / 毛重:4000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 油壓箱容量 | liters | 30 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 油壓泵浦馬達 | kW | 0.75 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 切削水容量 | liters | 200 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 切削泵浦馬達 | kW | 1 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 自動潤滑器容量 | - | 2 L,10c.c. / 10min | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 總電力 | Kva | 25 | 30 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

- 工件程式儲存3000M

- 圖形描繪功能

- 固定循環功能齊全

- 自動倒角/倒圓角功能

- X / Z軸同動功能

- RS 232C傳輸介面

- 刀具位置補正100組

- 刀尖圓弧補正功能

- 定表面速度控制功能

- 主軸定位功能

- C 軸功能

- 剛性攻牙

- 彈性筒夾式夾頭

- 八位伺服驅動刀塔

- 主軸分度裝置

- 自動潤滑系統

- 電氣箱冷卻器

- 冷卻、吹氣與油壓系統

- 前門安全裝置與工作燈

- 工具箱與隨機工具

- 成品接收裝置

- 自動送料裝置介面

- 超高壓冷卻系統

- TNS42筒夾副主軸

- 背面加工裝置

- 標準刀具組

- HAINBUSH筒夾式(主軸夾頭)

- 4”三爪夾頭副主軸

- HAINBUSH 32筒夾副主軸

- 副主軸內孔出水裝置(TNS)

- 伺服驅動裝置(背後加工用)

- VDI特殊驅動刀架

- 銑邊裝置(PGA)(T11用)

- 伺服驅動刀具(雙軸) (T11用)

- T12複合滑座裝置

- 切削液冷卻裝置

- 油霧收集器

- 排屑機與儲屑車(螺旋式/履帶式)

- 自動棒材送料機