- Home

- Products

- Turn-Mill CNC

- CNC Turret Type Automatic Lathe LND - AY SERIES

CNC Turret Type Automatic Lathe

LND-AY series is A Single Spindle CNC Lathe with Y-Axis Slide 8 /12-Position Live Tools Turret for very complicate Turn - Mill machining. A most basic CNC Control System can be intalled for lowest cost machine available. Siemens-802D, Mitsubishi-E68 will be good for this application.

| MODEL | LND42AY | LND65AY | ||

| Capacity | ||||

| Collet bar capacity ,dia. (thru hele) | mm | Ø42 | Ø65 | |

| Max. turning length | mm | Ø355 | ||

| Max. turning dia. (3-Jaw Chuck) | mm | Ø165 (Ø6.5”) | Ø210 (Ø8.3”) | |

| Max. turning length | collet chuck | mm | 300 (11.8”) | |

| 3-Jaw chuck | mm | 280 (11”) | 254 (10”) | |

| Spindle | ||||

| Height of spindle center (approx.) | mm | 1100 | ||

| Spindle nose | - | ISO A2-5 | ISO A2-6 | |

| Collet chuck type | - | F48 | F72 | |

| 3-Jaw chuck size | inch | 6 | 8 | |

| Spindle thru hole / draw tube thru hole | mm | Ø53/Ø45 | Ø78/Ø66 | |

| Power of spindle motor | Kw | 9 | ||

| Max. spindle speed | rpm | 5000 | 4000 | |

| Main slide | ||||

| Z-Axis slide travel | mm | S8LT:300 / S12LT:300 | ||

| X-Axis slide travel | mm | S8LT:150 / S12LT:150 | ||

| Y-Axis slide travel | mm | ±55 (110) | ||

| Resolution | mm | 0.001 (0.0001”) | ||

| Turret | ||||

| Number of tool position (BARUFFALDI S12LT / LICO S8LT) | _ | 12 / 8 | ||

| Type of tool shank | mm | Ø25 / □20mm (Ø1” / □3/4”) | ||

| Servo Motors | ||||

| Rapid move (X-Axis / Z-Axis) | mm/ mim | 20 | ||

| Rapid move (Y-Axis) | mm/mim | 8 | ||

| Feed rate | M/mim | 0 – 10000 | ||

| X / Z - Axis power | Kw | 2.29 | ||

| Y- Axis power | Kw | 1.48 | ||

| Hydraulic tailstock | ||||

| Quill diameter | mm | Ø 50 | ||

| Center taper | _ | MT-3 / MT-4 | ||

| Quill stroke | _ | 80 | ||

| Manual stroke | mm | 185 | ||

| Hydraulic pressure | Kg/cm2 | 5-30 | ||

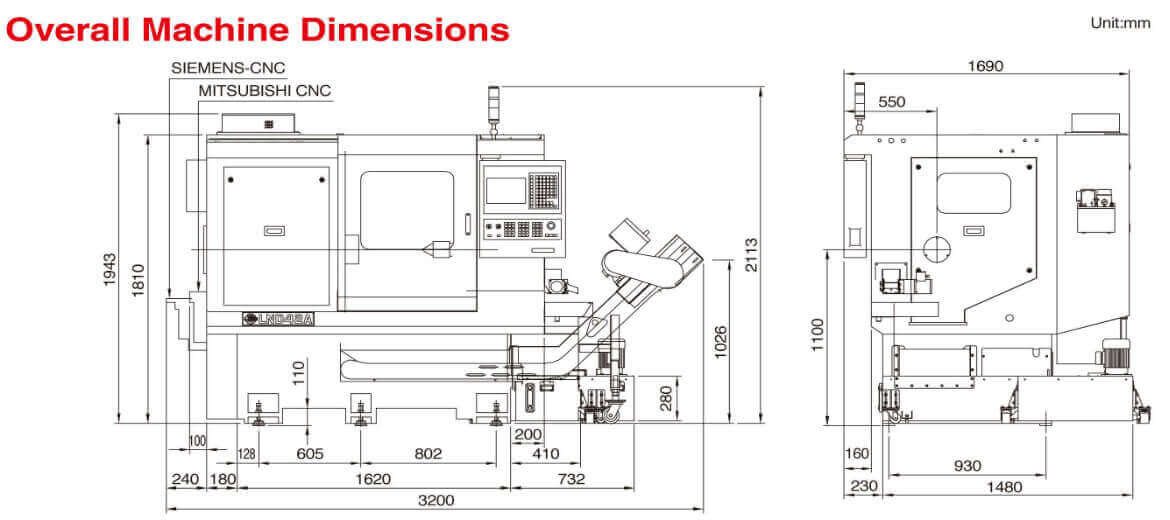

| Machine space , weight and power requirements | ||||

| Overall dimensions (L x W x H) | mm | 2780 x 1750 x 1950 | ||

| Machine weight | kgs | 3500 | 3600 | |

| Hydraulic tank capacity | liters | 35 | ||

| Hydraulic pump motor | liters | 0.75 | ||

| Coolant tank capacity | liters | 160 | ||

| Pump power | kW | 1.27 | ||

| Lubrication capacity | _ | 4 L,15 sec / 15min | ||

| Total power requirement | KVA | 20 / 25 | ||

- Collet chuck LND42AY F48 (Max. Ø42)

- Collet chuck LND65AY F72 (Max. Ø65)

- Hydraulic power system

- Coolant system

- Automatic lubrication system

- Parts catcher and parts conveyor

- Control cabinet heat exchanger

- Foot pedal for collet & chuck open/close

- Air jet system (include air blast)

- Work lamp

- Tool box & tool kits

- Automatic bar feeder interface

- Spindle brake and dividing system

- Tool turret 12 stations and tool holders

- 6” Hollow power chuck (LND42AY)

- 8” Hollow power chuck (LND65AY)

- Hydraulic tailstock MT-3 / MT-4

- Chip conveyor with cart

- Oil mist collector

- Tool turret 8 stations and tool holders

- Front door safety interlock (CE)